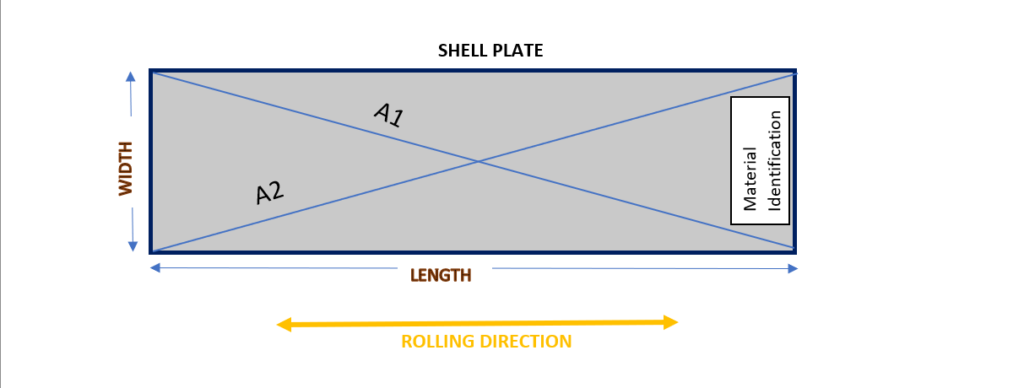

In the fabrication process of pressure vessel components, marking and cutting of shell plates require meticulous attention to detail. Here are essential points to ensure precision and quality:

• The plate is precisely cut to match the dimensions specified in the drawing.

• A bevel edge is meticulously prepared according to the drawing specifications.

• Cut edges are meticulously ground down to ensure they are sound, with a tolerance of 1 to 1.5 mm.

• Identification Markings are applied perpendicular to the rolling direction for clarity.

• Hard punching is avoided for ferrous plates thinner than 6mm and non-ferrous plates thinner than 12mm.

TOLERANCES:

1. Plate length and width: ± 1 mm per meter, with a maximum deviation of ± 3 mm.

2. A1-A2 measurement: ± 1 mm per meter, with a maximum deviation of ± 5 mm.