Dish ends are usually manufactured by cold or hot pressing. A combination of pressing and spinning is used for the manufacturing. Smaller dish with less than 800 mm diameter are made by cold or hot pressing while dish heads with larger diameter are manufactured by combination of pressing and subsequent spinning.

Semi Ellipsoidal dished End: It is most used dished ends in pressure vessels. Excluding the height of straight face, inside depth of the dish end is one half the inside radius of the dish i.e., depth of head which is a quarter of the vessel’s internal diameter. This is the reason it is called 2:1 Ellipsoidal.

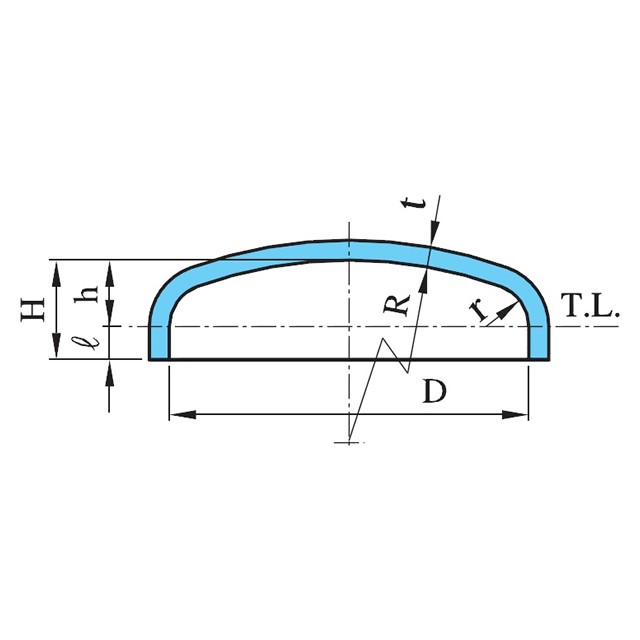

- Hemispherical Dished End: These are of hemispherical shape and manufactured same as ellipsoidal heads. The radius of the head equals the radius of the cylindrical part of the vessel.

Tori spherical Dished End: Tori spherical heads have a dish with a fixed radius, the size of which depends on the type of tori spherical head. The transition between the cylinder and the dish is called the knuckle. The knuckle has a toroidal shape.